Amidon iron powder toroids calculator

Iron Powder Cores are distributed air gap cores that are primarily used in power inductor applications. Powder Core materials are high resistivity, low hysteresis and eddy current losses and excellent inductance stability under both DC and AC conditions.

| Material type of the toroid – | ||

| Dimension type of the toroid – | ||

Available information about the toroid:

Color Code:Material:

Resonant circuit frequency range:

Initial magnetic permeability (μ):

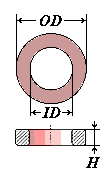

Dimensions (OD x ID x H):

AL factor: µH/(N/100)2

ENTER THE INPUT DATA:

| L | = | – Required inductance |

| N | = | – Number of turns |

The calculator uses the formula

L [µH] = AL * (N/100)2

One can use the Amidon ferrite toroids calculator

MATERIAL #0: Most commonly used for frequencies above 100 MHz. Due to the nature of this material the inductance resulting from the use of a given AL value may not be as accurate as we would like. Inductance vs. number of turns will vary greatly depending upon the winding technique.

MATERIAL #1: Very similar to material #3 except that it has higher volume resistivity and better stability.

MATERIAL #2: A Carbonyl 'E' iron powder material having high volume resistivity. Offers high 'Q' for the 2 MHz to 20 MHz frequency range.

MATERIAL #3: A Carbonyl 'HP' material having excellent stability and good 'Q' for the lower frequencies from 50 KHz to 500 KHz.

MATERIAL #6: A Carbonyl 'SF' material. Offers very good 'Q' and temperature stability for the 20 to 50 MHz frequency range.

MATERIAL #7: A Carbonyl 'TH' material. Very similar to the #2 and #6 materials but offers better temperature stability than either.

MATERIAL #8: This material has low core loss and good linearity under high bias conditions. A good high frequency material. The highest cost material.

MATERIAL #10: A powdered iron 'W' material. Offers good 'Q' and high stability for frequencies from 40 MHz to 100 MHz.

MATERIAL #12: A Synthetic oxide material which provides good 'Q' and moderate stability for frequencies from 50 MHz to 200 MHz. If high 'Q' is of prime importance this material is a good choice. If stability is of a prime importance, consider the #17 material.

MATERIAL #15: A carbonyl 'GS6' material. Has excellent stability and good 'Q'. A good choice for commercial broadcast frequencies where good 'Q' and stability are essential.

MATERIAL #17: This is a new carbonyl material which is very similar to the #12 material except tatar it has better temperature stability. However, as compared to the #12 material, there is a slight 'Q' loss of about 10% from 50 MHz to 100 MHz. Above 100 MHz, the 'Q' will gradually deteriorate to approximately 20% lower.

MATERIAL #18: This material has low core loss similar to the #8 Material with higher permeability and a lower cost. Good DC saturation characteristics.

MATERIAL #26: A Hydrogen Reduced material. Has highest permeability of all of the iron powder materials. Used for EMI filters and DC chokes.

MATERIAL #30: The good linearity, low cost, and relatively low permeability of this material make it popular in large sizes for high power UPS chokes.

MATERIAL #40: The least expensive material. It has characteristics quite similar to the very popular #26 Material. Popular in large sizes.

MATERIAL #52: This material has lower core loss at high frequency and the same permeability as the #26 Material. It is very popular for new high frequency choke designs.

Related links:

- Amidon™ Iron Powder toroids

- Inductor Cores: Material and Shape Choices

- How to choose Iron Powder, Sendust, Koolmu, High Flux and MPP Cores as output inductor and chokes